In the past, the word “automation” has created such a buzz, especially in the manufacturing industry. The discourse surrounding the use of robots in the processing and delivery of products is a hot topic of conversation throughout various industries. Majority shareholders are pushing top management officials to adopt automation due to the numerous benefits it brings. The overreaching goal is to seamlessly integrate it into their current processes to streamline their operations.

Since changes are inevitable and the fast-paced, dynamic shifts in both technology and customer demands are here, expectations are all pointing to the need for automation. Besides, rivals and competitors are bringing out the best of each other in terms of using robotics in manufacturing.

What are Some of the Emerging Technologies?

Depending on your manufacturing concern and goals, there are different automation options that you can contemplate for your business. The technologies vary with respect to the application and cost and return on investment (ROI). They also tend to have similarities with the common thread being the employment of control systems such as embedded computers, robots, and information systems.

.jpg?width=391&name=shutterstock_551791498%20(2).jpg) Artificial Intelligence (AI)

Artificial Intelligence (AI)

AI is one such application. AI, or machine intelligence is best manifested when you have smart manufacturing equipment installed at your production facility.

Smart means the machines are computer programmed to exhibit human-like traits of perceiving, reasoning, planning, solving problems, voice recognition, and moving items along the production line. It’s even more extreme when the automated machines have learning capabilities. It means the device iterates its performance based on experiences it picks up while on active duty. Alternatively, it can be reprogrammed and taught newer techniques to handle different aspects of production.

Robotics and Augmented Reality (AR)

The line between robotics and AI is thin. Specially designed robots get information from data and use this information to aid manufacturing processes. For example, robots can accurately set product control parameters and use these set parameters to ensure quality control. They can also remove a lot of the uncertainty from your desired outcomes. Since the process is automated, it won't deviate from the task you set it to do and produce consistent results.

You use the information collected by the robotic systems as your feedback for areas where you can potentially improve your production systems. It’s crucial in telling you what steps to take to improve production flaws, if any, by initiating corrective measures. It can also serve to compare your automated-manufacturing efforts to your industry benchmarks. Further, it can be utilised in yet another automation technology — AR. An example of the application of AR in the field of manufacturing is the development of prototypes.

You use the information collected by the robotic systems as your feedback for areas where you can potentially improve your production systems. It’s crucial in telling you what steps to take to improve production flaws, if any, by initiating corrective measures. It can also serve to compare your automated-manufacturing efforts to your industry benchmarks. Further, it can be utilised in yet another automation technology — AR. An example of the application of AR in the field of manufacturing is the development of prototypes.

Robotics and AR are quickly finding a permanent placement in manufacturing and other industry sectors. This brings a host of advantages that weren't possible before like a more efficient design process, a greater level of speed and precision and higher levels of flexibility.

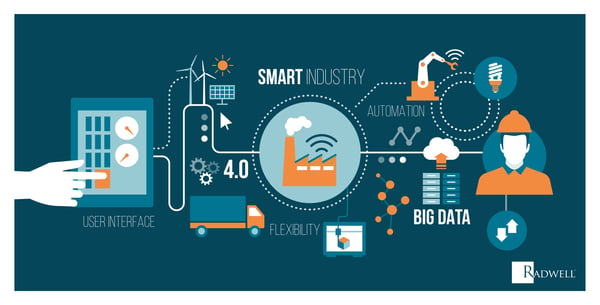

Internet of Things (IoT) and Industry 4.0

All automation technologies highlighted above tie to the IoT. What’s the relationship? The connection lies in understanding the precise definition of IoT: the interconnectivity of physical objects, industrial machines, or devices, if you may, through an internet protocol (IP) address. The objects here range from wearable devices to cars, home appliances, machines of all sorts. This linking of the objects could be on a localised or even global scale in terms of region.

As a manufacturer, you need to set up a framework that will support the interconnectivity of the equipment and devices that power your factory’s automation. Also, ensure you have a cyber-secured database or cloud backup for your big data and analytics. The purpose of such a foundation is to have the architecture for person-to-person (P2P), person-to-machine (P2M) and machine-to-machine (M2M) information exchanges that are the backbone of automation in manufacturing.

The Impact of Automation in Driving Manufacturing

Automation has changed manufacturing unprecedentedly. Automated plants can now run almost continuously throughout the year with periodic breaks for holidays, maintenance and stock taking. Machines are in a position to run 24 hours a day, and this increases your production and output. The computers control the inputs and conversion of raw materials. They instantly flag errors or omission in the production line. The result is accurate, high-quality products, and minimal wastage of materials. Further, most of these machines are flexible enough to be reprogrammed to produce a variety of products with swift changeovers in between such that you save manufacturing lead-time.

The data collected by the IIoT is crucial in gathering manufacturing metrics. The information goes into your decisions concerning efficient energy consumption, useful process improvements, and consequently, a reduced environmental footprint.

The data collected by the IIoT is crucial in gathering manufacturing metrics. The information goes into your decisions concerning efficient energy consumption, useful process improvements, and consequently, a reduced environmental footprint.

The initial capital outlay for an automated facility will significantly set you back financially, but automated manufacturing has also seen firms save costs. In the long run, you have an optimal labour component that has high-level skills; you produce more output; you enjoy smooth integration between hardware and software controls; there is the safe and best use of factory space, a competitive edge and better planning which translates to faster ROI.

The Future of Manufacturing

Martin Thomas, European Marketing Manager at Radwell said “Automation will continue to define how fast products arrive at your doorstep since it runs on technology. With technologies rapidly changing every other day, it will lead to improvements or complete changes in current manufacturing automation. Complementing factors such as cheaper and renewable energy sources (including natural and nuclear), widespread broadband internet connection at lower costs, and an in-demand skills workforce will serve to empower even more automation in manufacturing.

Also, customers are increasingly demanding. The 21st-century consumer is enlightened. Today’s customers have realised that there exists a body of useful information out there concerning products and services. Besides, the unlimited offerings warrant some level of research in the making of purchase decisions. You must be customer oriented and tie your big data and customer feedback to your manufacturing automation.”

Finally, with automation becoming more user-friendly and accessible to the general public, it's projected to take over the future of manufacturing. Manufacturers want consistent results of the highest quality, and automation all but guarantees it. Going forward, you'll see more automation in the manufacturing sector, and you'll see an improvement in every stage of the manufacturing process.